-

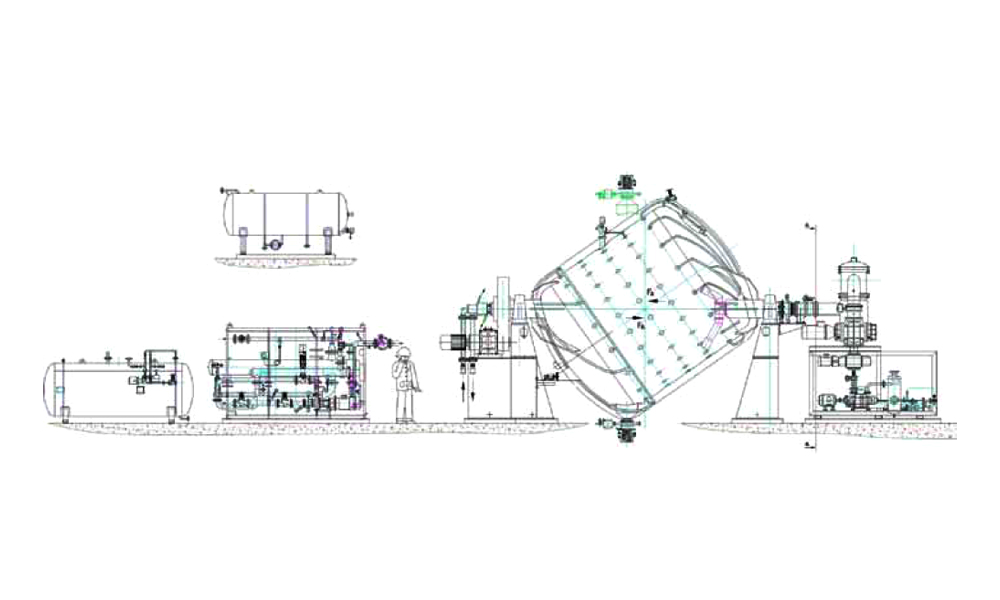

배치식 고상중합Vacuum Tumbler Reactor(BATCH SSP)

Bottle to Bottle FDA승인 PET재생라인

고상중합 공정은 1mbar absolute의 진공하에서 최대 250℃로 가열이 됩니다.

카탈로그 다운로드

- 주요 처리 소재PET, PBT, PEN, PA6, PA66 etc

- 주요 용도Bottle, Fiber, Industrial Yarn(광케이블, 타이어코드, 에어백, 필터소재, 어망 등)

- 공정고상중합 공정은 1mbar absolute의 진공하에서 최대 250℃로 가열이 됩니다. 공정은 Batch 공정으로 이루어지며, 저희는 이 분야에서 200대 이상의 실적을 가지고 있고, 국내에도 다수의 실적을 보유 중입니다.

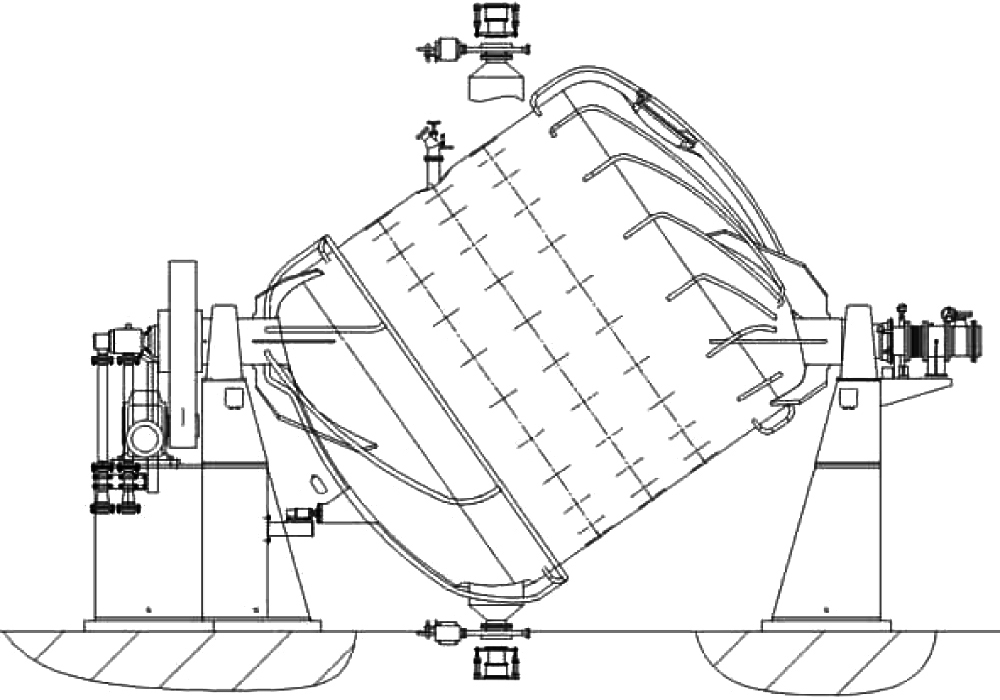

- 1. Reactor

- 2. Heating/cooling system

- 3. Vacuum pump station

- 4. Automatic operation (for automatically filling and discharging the reactor)

- 5. Control system with switch cabinet

| Type |

Filling with pellets in kg |

Output drive motor in kW ① |

Heating in kW ② |

Suction capacity vacuum pump station in m³/h |

| TTR 16 |

~ 9,500 |

9 |

210 |

~ 4,000 |

| TTR 24 |

~ 14,300 |

15 |

280 |

~ 4,000 |

| TTR 36 |

~ 21,400 |

22 |

350 |

~ 8,000 |

| TTR 44 |

~ 26,200 |

30 |

500 |

~ 12,000 |

- ① Material with bulk density of 0.85kg/1

- ② Final specification is dependent on the process

| Additional data |

| Speed range |

05 to 2 rpm |

| Vaccum |

< 1 mbar abs. |

| Leakage rate |

< 0.1 mbar*l/x |

| Maximun operating temperature |

250°C |

The reactor

For heating of the plastic pellets, the reactor is equipped with a double jacket through which the tempered heat transfer oil flows. The oil is fed in through a rotary joint on one of the two shafts. The opposite shaft is connected to the interior and is used to extract the vapors. The reactor is actuated by a reduction gear and can revolving within a speed range of 0.5 to 2 rpm - depending on the requirements of the process.